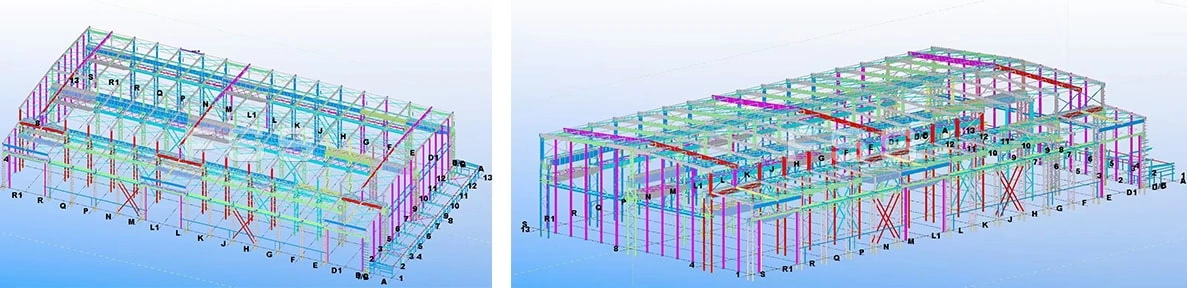

This project involves the construction of a 25,890-square-meter steel structure workshop equipped with heavy-duty overhead cranes (75-ton lifting capacity). The structural design features steel columns using tubular truss structures, welded H-section steel beams, and welded H-section and box girders for crane beams. The project highlights advanced engineering precision, high welding demands, and efficient execution. Below is a detailed breakdown of the key phases.

Heavy Welding Workload: Over 1,200 tons of steel processed, with welded joints exceeding 8,500 linear meters. Automated submerged arc welding (SAW) ensured consistent quality.

Large Component Fabrication:

Tubular Truss Columns: Prefabricated in segments (max weight: 28 tons) using CNC cutting and robotic welding.

Crane Beams: Combined H-section and box girders reinforced with stiffener plates to withstand 75-ton dynamic loads.

Quality Control: UT/MT testing applied to 100% of critical welds; dimensional tolerances maintained within ±3mm.

Key Challenge: Balancing production speed with stringent tolerances for heavy components.

Steelwork company

fabrication and welding

steelwork company

metal fabricators

Steelwork company

Steelwork company

metal fabricators

Steelwork company

Heavy Lifting Strategy: Deployed 500-ton crawler cranes for tubular truss column installation (average lift height: 22m).

Precision Alignment: Laser-guided alignment tools ensured column verticality within 1/1,000 tolerance.

Sequential Assembly: Prioritized main frame erection (columns + beams) followed by crane girder installation.

Safety Protocols: Real-time monitoring of wind speeds and load distribution during lifts.

Key Milestone: Full structural frame completed 5 days ahead of schedule.

Precision-Driven: Tubular truss column assembly demanded sub-5mm joint accuracy.

Heavy Fabrication: 85% of components weighed over 15 tons, requiring specialized handling.

Rapid Execution: Completed design-to-installation in 172 days, showcasing integrated engineering capabilities.

This solution ensures end-to-end adherence to global standards, combining advanced software, rigorous quality protocols, and logistics optimization. For full details, refer to the cited standards and specifications.

*Required fields