FSS company is a professional steel structure product design, production, manufacturing and installation integration company, we can provide comprehensive steel structure product solutions for customers sincere professional service.

China Standard: Adhere to GB 50017-2017 Code for Design of Steel Structures, selecting materials such as Q345B (yield strength: 345 MPa) or Q235B (yield strength: 235 MPa) steel grades. Key standards include GB/T 700-2006 for carbon steel and GB/T 1591-2008 for low-alloy steel.

USA Standard: Follow AISC 360-22 Specification for Structural Steel Buildings, using ASTM A992 (Fy = 50 ksi) or ASTM A36 (Fy = 36 ksi).

Europe Standard: Comply with EN 1993-1-1 (Eurocode 3) and select steel grades like S355 (yield strength: 355 MPa) or S275.

Product Design Specifications

Design calculations include load analysis (dead, live, wind, seismic), joint detailing, and stability checks.

Standardized product models (e.g., H-beams, BOX-sections, TUBE truss sections) are selected based on span, load capacity, and regional code requirements.

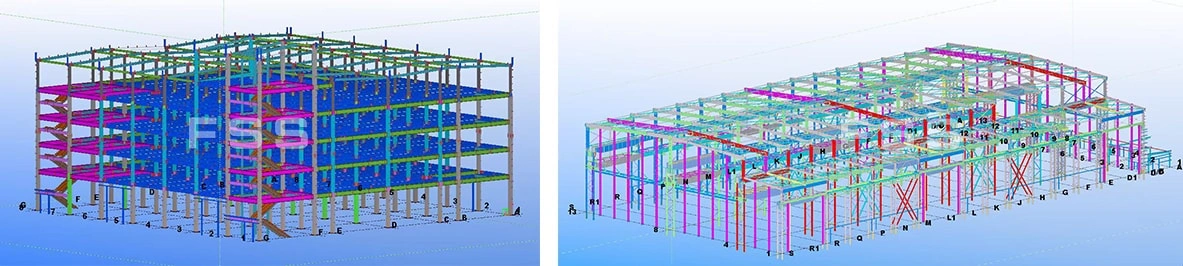

Utilize Tekla Structures to create accurate 3D models, incorporating code-compliant connections (e.g., bolted, welded).

Generate shop drawings with precise dimensions, weld symbols, and bolt specifications.

Key Deliverables :

Assembly Drawings: Highlight component positioning and welding/bolting sequences.

Part Lists:

Detailed material specifications (e.g., plate thickness, bolt grades).

Clash Detection:

Resolve conflicts in complex assemblies before fabrication.

Quality Assurance

Cross-check drawings against GB 50205 (China), AWS D1.1 (USA), or EN 1090 (Europe) for compliance.

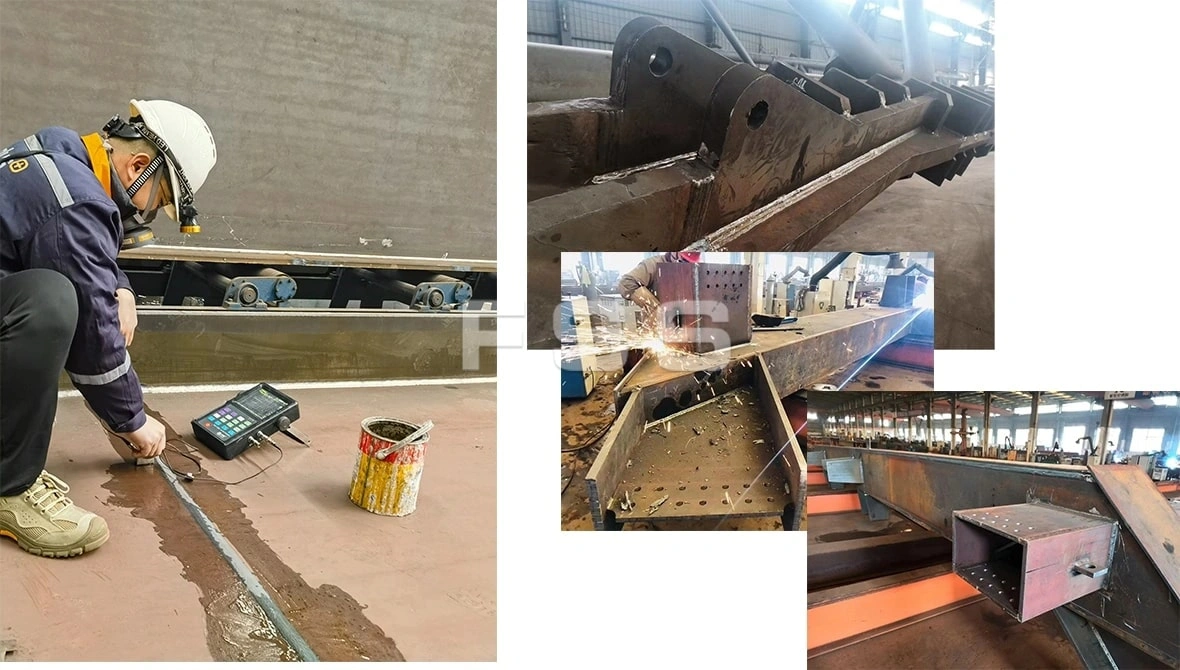

Material Inspection : Verify steel certificates (e.g., GB/T 700, ASTM A6) and conduct mechanical tests (tensile, impact).

Cutting: CNC plasma/oxy-fuel cutting with ≤2mm tolerance.

Welding:Follow qualified procedures (e.g., GB 50661 for China, AWS D1.1 for USA).

Full-penetration welds for critical joints (e.g., beam-column connections). Bolt Hole Drilling: Ensure hole alignment within ±1.5mm tolerance.

Dimensional Accuracy:Use laser scanning to validate component geometry.

Non-Destructive Testing (NDT):Ultrasonic Testing (UT) for full-penetration welds (Grade B per GB 11345 for China). Magnetic Particle Testing (MT) for surface cracks.

Coating Inspection: Confirm anti-corrosion coatings meet standards (e.g., GB/T 8923 for surface preparation, ISO 12944 for paint systems).

Steel Pallets : Secure components with wooden and steel frame (e.g., Packing belt).

Marking: Label each package with project ID, weight, and handling instructions per ISO 780. Container Loading Optimize space using CAD-based loading plans to prevent deformation during transit. Use twist locks and dunnage bags to immobilize cargo within containers.

Documentation: Provide Mill Certificates, NDT reports, and Packing Lists compliant with destination regulations (e.g., CE marking for Europe, AISC certification for USA).

China Standard:GB 50205-2020《Code for Acceptance of Construction Quality》.

USA Standard:AISC Certified Fabricator Program.

Europe Standard:EN 1090-1 (Execution Class 2-4).

This solution ensures end-to-end adherence to global standards, combining advanced software, rigorous quality protocols, and logistics optimization. For full details, refer to the cited standards and specifications.

*Required fields