Prefabricated steel frame houses combine rapid delivery, cost efficiency, and sustainable materials with modular designs for durable, energy-efficient homes built in weeks instead of months.

Prefabricated Steel Frame Houses offer innovative solutions for modern housing needs:

Rapid-deploy pre fab structure units for disaster relief, using prefabricated steel frames to withstand extreme weather (wind speeds up to 200 km/h).

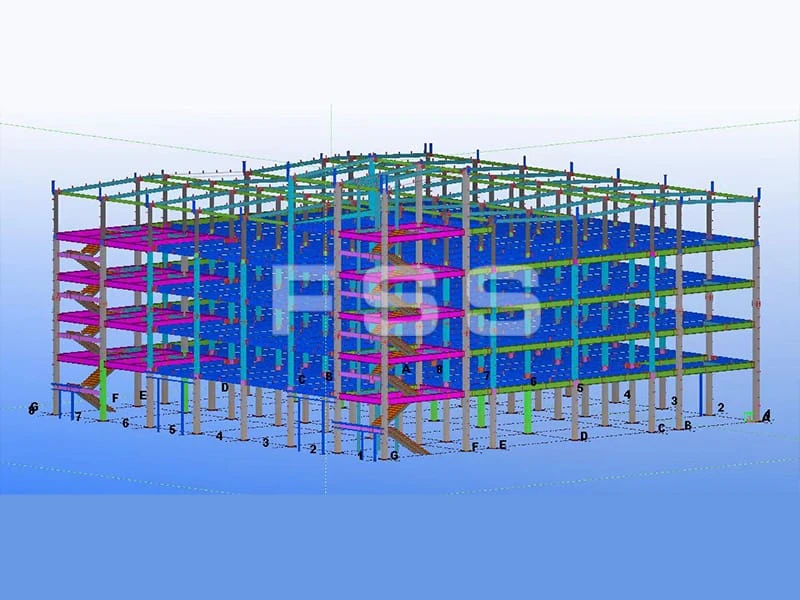

Stackable home prefabricated units with open-plan layouts, combining prefabricated steel beams and prefab wall panels for quick on-site assembly.

Bespoke prefabricated steel frame houses with vaulted ceilings and large windows, fabricated offsite to reduce on-site labor by 60%.

Energy-efficient pre fab structure homes with solar-ready roofs and recycled steel materials (up to 40% post-consumer content).

Compact prefabricated steel cabins for off-grid living, pre-insulated and pre-wired for easy installation in rural areas.

| Stage | Techniques& Materials | Performance Metrics |

|---|---|---|

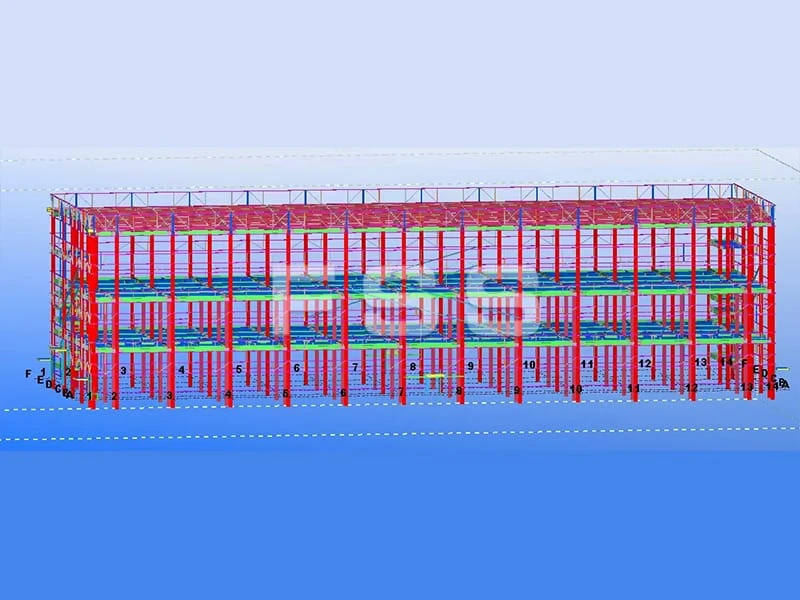

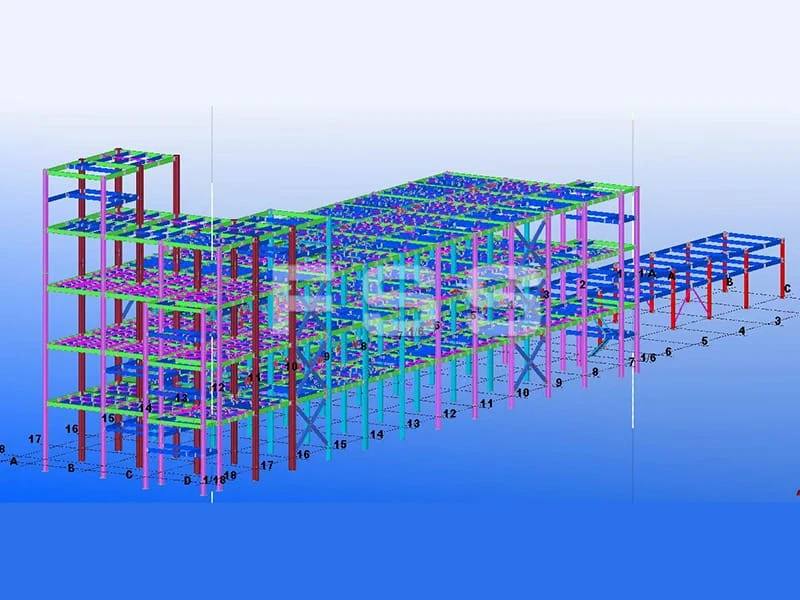

| Design& Engineering | BIM modeling for prefabricatedsteel frame houses; structural simulations for seismic loads | Wind resistance: 180 km/h |

| Steel Fabrication | Laser-cutting prefab sstructureomponents; automated welding for prprefabricatedesteelms | Tolerances: ±1mm on flange alignment |

| Panel Assembly | Pre-assembled wall/roof panels with insulation cores; bolted connections for homepprefabricatednits | Load capacity: 3,000 kg per panel |

| Surface Finishing | Powder coating + fire-retardant paint for prefabricatedssteelurfaces | Salt spray resistance: 800+ hours |

| Quality Tagging | QR code labels track prefab sstructureatches from factory to site | 100% compliance with ASTM A1085 standards |

Material Certification: Third-party verification of prefabricated steel (ASTM A709 Grade 50).

Structural Testing: Load simulations for prefabricated homes under wind (200 km/h) and snow (5 kN/m²) loads.

Thermal Performance: blower door tests (ACH 1.5) and U-value measurements for energy efficiency.

Fire Safety: ASTM E84 flame spread index ≤25 for prefabricated steel wall panels.

Certifications: ISO 9001:2015 and LEED v4 compliance for pre fab structure factories.

Modular Shipping: Pre-assembled prefabricated steel frame houses components fit in 20ft/40ft containers, reducing transport costs by 35%.

Protective Packaging: Custom cradles shield pre fab structure units during transit, preventing scratches or warping.

Global Logistics: Flat-rack shipping for oversized prefabricated home roofs (widths up to 6m) with self-propelled modular trailers (SPMT).

On-Site Erection: Pre-drilled anchor points and color-coded connections accelerate assembly by 70% vs. traditional builds.

Carbon-Neutral Options: Biofuel-powered shipping reduces emissions by 25% per project.

*Required fields