This steel structure warehouse represents a milestone in industrial infrastructure development for Johannesburg, combining cutting-edge engineering with rapid execution. Designed for high-capacity metal casting operations, the project was delivered by a leading steel building company in collaboration with local metal building suppliers, ensuring compliance with South African construction standards. Spanning over 3,000 tons of fabricated steel, the facility underscores the versatility of engineered steel buildings in addressing complex industrial requirements. Completed within 12 months, it highlights the synergy between advanced manufacturing practices and strategic project management, offering a scalable solution for future industrial expansion in the region.

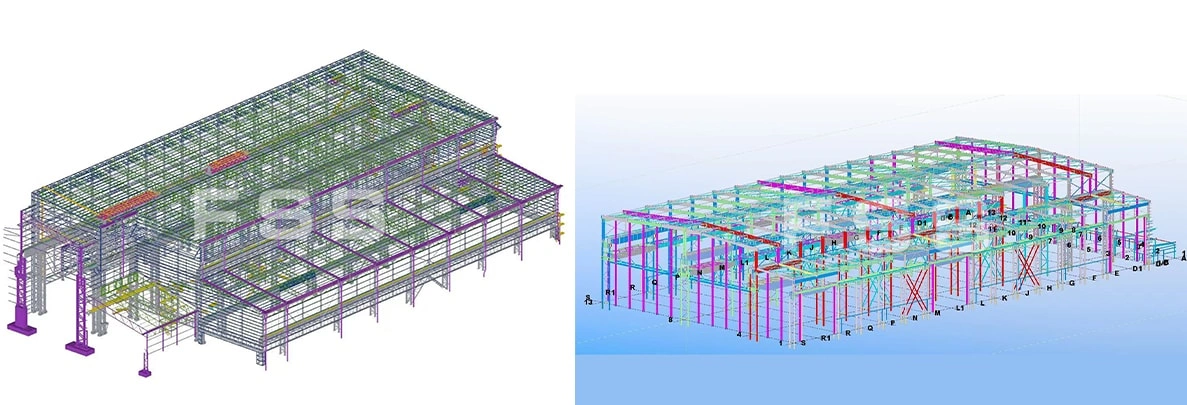

This project showcases a heavy-duty steel casting workshop located in Johannesburg, South Africa, engineered to meet the demands of large-scale industrial manufacturing. The metal frame buildings structure features a robust steel framework with a maximum crane gantry load capacity of 120 tons, supported by columns weighing over 30 tons each. Spanning an expansive footprint, the workshop’s design prioritizes load-bearing efficiency and spatial flexibility, utilizing engineered steel buildings principles to optimize structural integrity.

The framework integrates high-strength H-beams and custom-welded columns, strategically designed to distribute loads evenly across the 3,000+ ton structure. The crane gantry system, a critical component for heavy material handling, was engineered with redundant safety factors to ensure reliability in continuous industrial operations. This project exemplifies the capabilities of steel building manufacturers to deliver bespoke solutions for extreme engineering challenges.

From raw material selection to on-site assembly, the fabrication of this workshop highlights precision engineering. The process began with laser-cutting high-tensile steel plates into precise components, followed by robotic welding to ensure consistency in joint strength. Columns and beams underwent rigorous quality inspections, including ultrasonic testing and load simulation, to meet ISO standards.

A standout feature is the modular assembly approach, where pre-fabricated sections were fabricated off-site by metal building suppliers in compliance with the project’s tight tolerances. Over 3,000 tons of steel were produced in 12 months, a testament to the efficiency of steel building company workflows. The assembly phase prioritized phased coordination, with cranes and rigging systems synchronizing the installation of heavy columns and beams to millimeter accuracy.

This project underscores the superiority of engineered steel buildings in industrial applications. Key advantages include:

Durability: Corrosion-resistant coatings and thermal expansion-resistant designs ensure longevity in South Africa’s variable climate.

Cost Efficiency: Pre-fabrication reduced on-site labor by 40%, accelerating project delivery while maintaining quality.

Sustainability: Steel’s recyclability aligns with global ESG goals, offering a 70% reduction in lifecycle carbon compared to concrete alternatives.

The workshop’s design also maximizes usable space, with a clear height of 15 meters and column-free spans, ideal for casting operations. By leveraging the expertise of leading steel building manufacturers, this project sets a benchmark for industrial infrastructure, combining safety, scalability, and operational flexibility.

Delivered on time and within budget, this steel structure warehouse exemplifies the technical prowess of steel building companies. Its successful installation reinforces confidence in steel as the material of choice for high-load industrial facilities worldwide.

*Required fields