your trusted partner in innovative bridge engineering solutions!

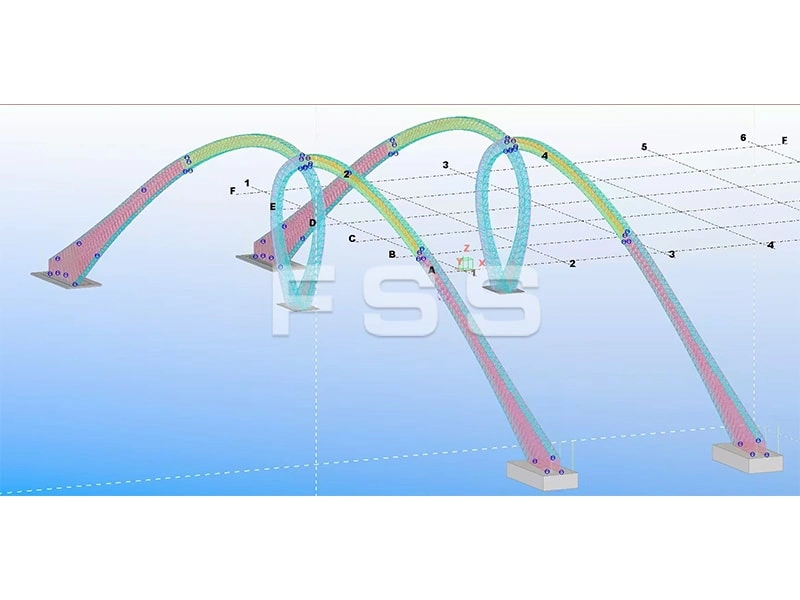

Arch Bridge solutions leverage bridge steel to deliver iconic and durable structures for diverse infrastructure needs:

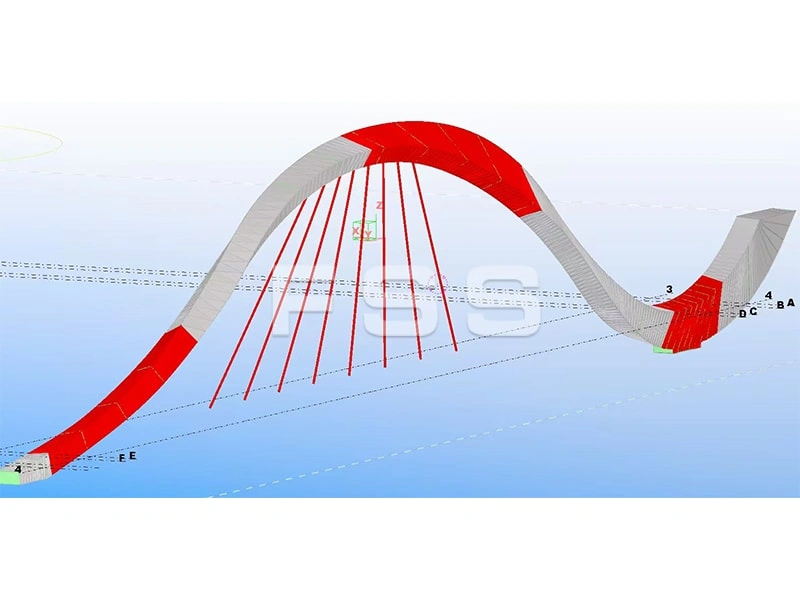

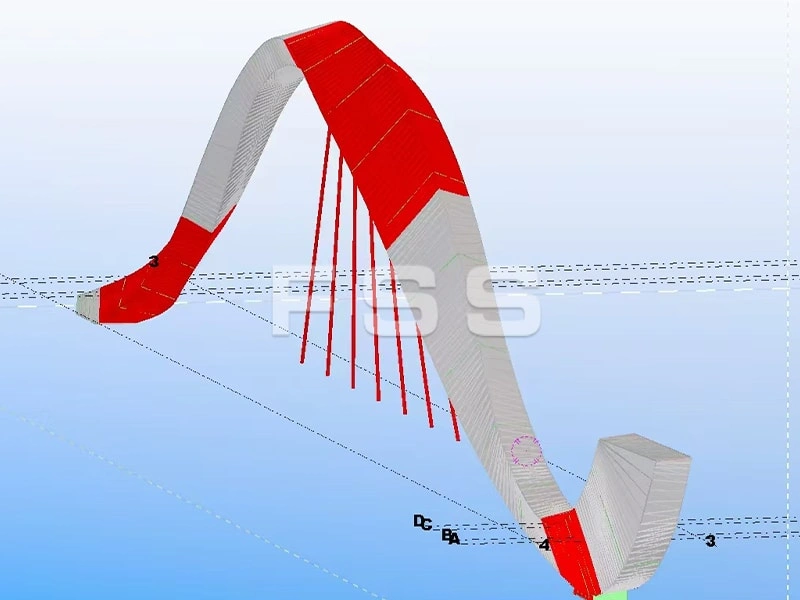

Hybrid arch bridge designs combining steel arches with cable systems for long-span river crossings, balancing aesthetics and load distribution.

Reinforced bridge steel arches for mountainous terrains, offering 30% higher rigidity than traditional truss systems to withstand landslides.

Curved truss girder arches for pedestrian promenades, integrating pre-fabricated segments for rapid assembly.

High-strength bridge steel arches for high-speed rail lines, designed with expansion joints to tolerate thermal shifts (-40°C to +60°C).

Custom arch bridge restorations using weathering steel (ASTM A588) to mimic aged patinas while meeting modern safety codes.

| Stage | Techniques& Materials | Performance Metrics |

|---|---|---|

| Structural Design | BIM modeling for cablestayed bbridgeybrid arches; parametric simulations for wind loads | Wind speed resistance: 200 km/h |

| Steel Fabrication | Laser-cutting bridge steel plates for arch ribs; automated orbital welding (AWS D1.5) | Tolerances: ±1mm on curved surfaces |

| TrussGirder Assembly | Pre-assembled rigidframe bbridgerusses using bolted connections for field adjustability | Load capacity: 5,000 kN per span |

| Surface Coating | Hot-dip galvanizing (HDG) + polyurethane paint for trussggirderrches | 1,200+ hours salt spray resistance |

| Final suspection | 3D LiDAR scanning validates archbbridgeeometry against CAD models | ±2mm dimensional accuracy |

Material Certification: Third-party verification of bridge steel chemical composition (ASTM A709 Grade 100).

Fatigue Testing: Simulated 1 million cycles of dynamic loads (train/vehicular) on truss girder arches.

Seismic Performance: Pseudo-static tests (0.5g acceleration) for rigid frame bridge arches in high-risk zones.

Coating Integrity: ASTM B117 salt spray trials and adhesion checks (ASTM D4541) for coastal installations.

Certifications: Compliant with Eurocode 3 (BS EN 1993-2) and AASHTO LRFD standards for cable-stayed bridge components.

Modular Arch Segments: Pre-assembled bridge steel arch halves ship in 40ft containers, reducing onsite crane time by 50%.

Custom Cradles: Patent-pending foam-lined supports protect truss girder arches during transit, preventing deformation.

Global Logistics Network: Flat-rack shipping for oversized rigid frame bridge components (heights up to 12m) with SPMT tractors.

On-Site Erection: Pre-drilled bolt holes and color-coded flanges accelerate arch bridge assembly by 30%.

Eco-Friendly Options: Carbon-neutral shipping via rail/sea routes, offsetting emissions by 25% per project.

*Required fields