Bridge Steel solutions are engineered for durability and precision in modern infrastructure projects:

Modular steel truss bridge frameworks for long-span crossings, combining lightweight efficiency with 100-year service life.

Pre-fabricated steel beam bridge components for urban overpasses, optimized for rapid installation and load adaptability.

Rapid-deploy structural steel bridge systems for emergency repairs or rural infrastructure, reducing construction time by 50%.

Customizable steel frame bridge designs for pedestrian walkways and architectural landmarks, featuring bolted connections for easy assembly.

High-strength steel truss bridge solutions for railway viaducts, with corrosion-resistant coatings (Hot-Dip Galvanized + Aluminized) for extreme climates.

| Stage | Techniques & Materials | Key Features |

|---|---|---|

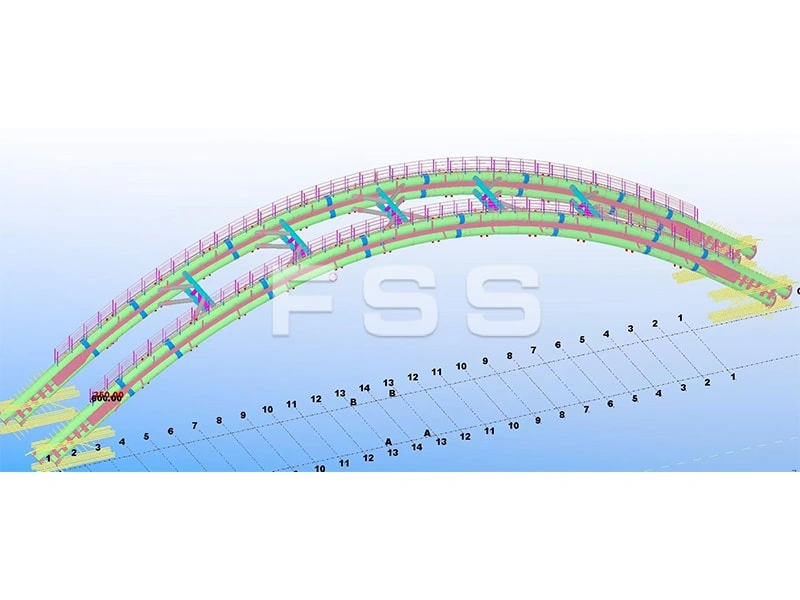

| Design & Prototyping | BIM modeling for steel truss arch bridge geometries; 3D laser scanning for fitment validation | ±1mm precision in joint alignment |

| Material Cutting | CNC plasma cutting for steel beam bridge flanges; automated nesting reduces waste by 20% | Tolerances: ±0.5mm on web thickness |

| Welding & Assembly | Friction stir welding (FSW) for structural steel bridge connections; robotic TIG for thin-gauge plates | Zero spatter, full penetration welds |

| Surface Protection | Galvanized coating (600g/m²) + polyurethane paint for steel frame bridge elements | Salt spray resistance: 800+ hours |

| Quality Tagging | QR code labels track prefabricated steel bridge components through supply chain | 100% compliance with AASHTO M270 standards |

Load Testing: Static load simulations (up to 3,000 kN) for steel truss bridge trusses using hydraulic actuators.

Fatigue Resistance: Cyclic loading tests (2 million cycles) for steel beam bridge spans per Eurocode 3 standards.

Coating Integrity: Salt spray testing (ASTM B117) and adhesion checks (ASTM D4541) for structural steel bridge elements.

Geometric Accuracy: Laser scanning verifies steel frame bridge alignment with ±2mm deviation tolerance.

Certifications: Third-party validation of AWS D1.5 bridge welding codes and EN 1090-2 execution standards.

Lightweight Modular Design: Pre-assembled steel truss arch bridge sections ship in 40ft containers, reducing transport costs by 30%.

On-Site Ergonomics: Custom cradles protect steel beam bridge beams during transit, preventing warping and coating damage.

Global Reach: Flat-rack shipping for oversized structural steel bridge components (widths up to 4m) with self-propelled modular trailers (SPMT).

Just-In-Time Delivery: GPS-monitored shipments with ±4-hour precision for prefabricated steel bridge projects.

Eco-Friendly Logistics: Carbon-neutral shipping options via optimized routes, cutting emissions by 20% per shipment.

*Required fields