Steel Frame Stadiums revolutionize modern sports infrastructure with unmatched versatility:

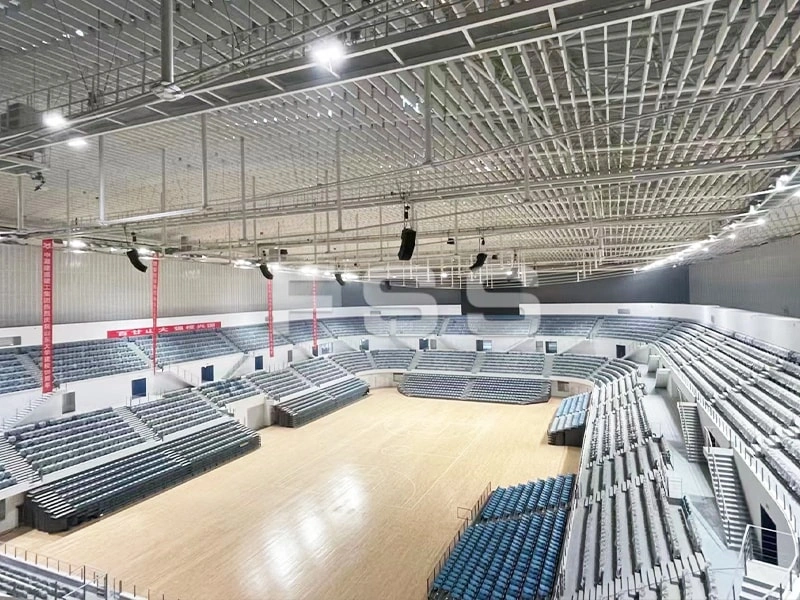

Customizable metal structure arenas for football, basketball, and concerts, featuring retractable seating and 360° sightlines.

Steel frame stadiums with wind-resistant trusses (up to 150 mph) and heated floors for year-round events in extreme climates.

Solar-ready roofs and rainwater harvesting systems in pre-engineered steel sports venues, achieving LEED Platinum certification.

Quick-add modules for expanding seating capacity (up to 50,000 seats) without structural overhauls.

Reinforced steel frame building retrofits for aging stadiums, preserving heritage while upgrading to modern safety standards.

| Phase | InnovativeTTechniquesechniques | PerformanceMMetricsetrics |

|---|---|---|

| StructuralDDesignesign | BIM 360 modeling with wind tunnel simulations for metalstructure aarenasrenas | 30% lighter frames vs traditional methods |

| PrecisionFFabricationabrication | Automated plasma cutting (±0.3mm tolerance) + robotic welding for roof trusses | Zero defects in critical load-bearing joints |

| SurfaceTTreatmentreatment | Galvanized coating (HDG) + anti-corrosion powder coating (500+ hours salt spray) | 30-year durability warranty |

| OnSite AAssemblyssembly | Bolted connections + snap-lock joint systems for rapid deployment | 60% faster installation vs poured concrete |

| QualityVerification | 3D LiDAR scanning for dimensional accuracy; thermal imaging for weld integrity | 100% compliance with ASTM A1065 standards |

Material Traceability: RFID tagging of all steel plates for real-time alloy verification (ASTM A709 Grade 50).

Dynamic Load Testing: Simulated crowd pressure (2,500 lbs/ft²) and seismic events (Zone 9) on steel frame stadiums.

Weatherproofing: Air leakage tests (≤0.25 L/(s·m²)) and ice dam resistance protocols for roof panels.

Acoustic Performance: Sound absorption coefficients ≥0.85 for spectator stands in metal structure arenas.

Safety Audits: Third-party inspections for fire-rated stairwells and emergency egress pathways.

Knockdown Kits: Disassembled steel frame stadiums ship in 40ft containers (capacity: 80 tons) with modular numbering for rapid reassembly.

Heavy-Lift Solutions: Self-propelled modular transporters (SPMTs) handle 500-ton roof sections for remote sites.

Global Warranty: Onsite technical support in 25+ countries during the 20-year service life of pre-engineered steel sports venues.

Carbon-Neutral Shipping: Biofuel-powered freight options offset 100% of CO₂ emissions for international projects.

*Required fields