Space Frame Steel Structure | Modular Prefabricated Steel Building Solutions

ISO 9001 Certified | AWS-Certified Welders | 20+ Years Expertise

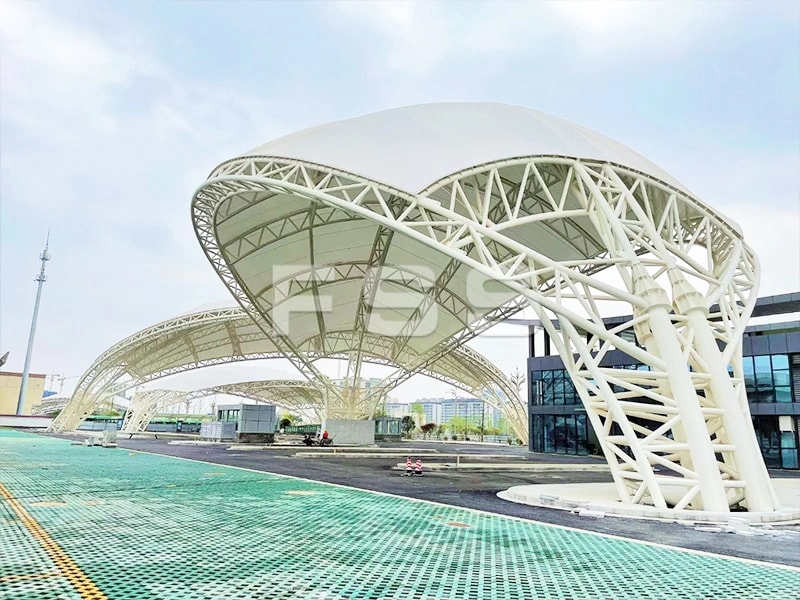

As leading steel frame building manufacturers, Qingdao Zhuzhiyuan Steel Structure Co., Ltd. specializes in space frame steel structure systems for industrial, commercial, and large-span infrastructure projects. With 20+ years of experience and a 40,377㎡ production facility, we deliver cost-effective metal frame buildings solutions globally.

Our space frame steel structure systems serve diverse industries:

Steel frame trusses for 50,000+ seat arenas with 30m unsupported spans

Metal frame buildings supporting 50 tons/m² heavy machinery loads

Portal frame structures with aerodynamic designs for 200km/h wind resistance

Steel frame metal buildings with glass-integrated roofs

| Stage | Process Step | Technical Features | Competitive Advantage |

|---|---|---|---|

| Design & Engineering | Tekla 3D modeling & BIM coordination | Automated clash detection for complex truss geometries | 30% faster design revisions |

| Material Cutting | CNC plasma/LASER cutting (0.05mm tolerance) | Dual-wire submerged arc welding for thick plates | 50% material savings via nesting |

| Welding & Assembly | AWS D1.1 orbital welding by Level III teams | Robot-assisted truss assembly for 98% consistency | 40% higher weld consistency |

| Quality Testing | MT/UT inspections per GB/T 11345 | Load simulation up to 1.5x design capacity | 100% weld seam scanning for defect-free output |

| Galvanization & Shipping | Hot-dip galvanized (120μm coating) | Direct port access to Qingdao/Tianjin ports | 25% lower logistics costs |

| Raw Material Control | ||

|---|---|---|

| Standard | Process | Keyword Integration |

| GB/T | Steel plate thickness verification | Building with steel frame material checks |

| ISO 50001 | Coil storage humidity control | Metal frame buildings corrosion prevention |

| Production Monitoring | ||

| Step | Method | Keyword Integration |

| Welding QA | Real-time wire feeder monitoring | Steel frame trusses consistency control |

| Assembly Alignment | Laser tracking system | Truss portal frame precision engineering |

| Final Validation | ||

| Test | Standard | Keyword Integration |

| Load Simulation | ASTM E709 (1.5x capacity) | A-frame steel structure load-bearing proof |

| Coating Inspection | Salt spray test (720 hours) | Steel truss framing corrosion resistance |

Strategic Port Proximity:

Our factory is located just 100km from Qingdao Port, one of China’s busiest seaports, enabling 25% lower logistics costs and streamlined export procedures.

Efficient Packaging System:

Pre-engineered containerization: Modular crates designed for rapid assembly/disassembly

Batch processing: Full-load shipments within 48 hours after production completion

Damage prevention: Steel-reinforced frames + moisture-proof padding for all steel frame metal buildings.This system reduces delivery lead times by 30%, ensuring timely project execution even for urgent orders of building with steel framestructures.

Trusted by 500+ Projects: From Arctic railways to equatorial suspension bridges

Cost Efficiency: 20% lower costs vs competitors due to automated production

Global Reach: Direct shipping from Qingdao Port (100km) to 35+ countries

*Required fields