Pre-Engineered Steel: The Future of Efficient Durable Steel Construction

In modern construction, pre engineered steel has emerged as a game-changer—combining precision engineering, rapid installation, and cost-effectiveness to redefine how structures are built. Unlike traditional methods, pre-engineered steel systems are fabricated off-site to exact specifications, minimizing on-site labor, waste, and delays. This approach integrates advanced technology with robust materials, making it ideal for diverse applications, from residential homes to industrial workshops. Below, we explore how pre engineered steel elevates key construction scenarios.

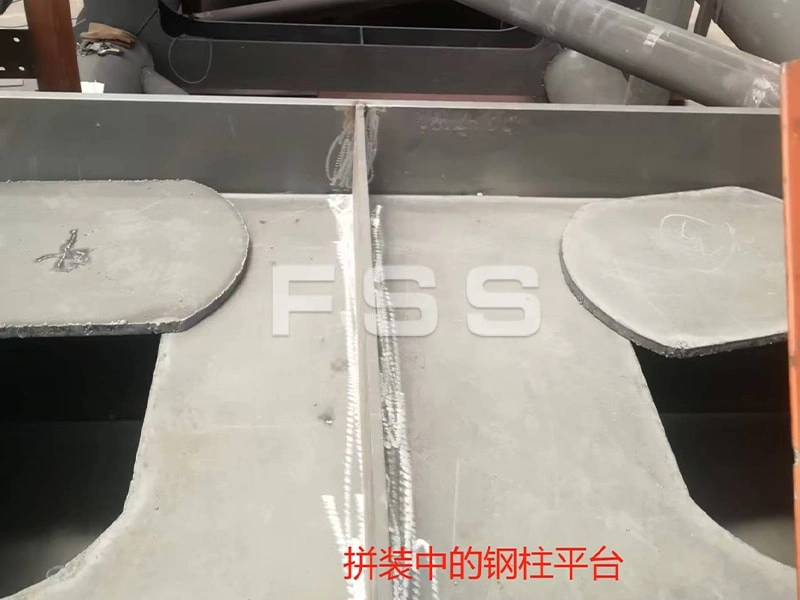

At the core of pre engineered steel solutions lies the steel frame structure building—a framework of vertical columns and horizontal beams engineered to distribute loads efficiently. These frames, typically made from high-strength steel (e.g., ASTM A992), offer unmatched flexibility: they can span large distances (up to 50m) without intermediate columns, maximizing usable space. For commercial buildings like warehouses, offices, or retail spaces, this means open floor plans, high ceilings, and easy adaptation to future expansions. In seismic zones, steel frames excel due to their ductility, absorbing and redistributing energy during earthquakes—making them safer than rigid concrete structures.

Pre engineered steel has revolutionized metal home construction, offering homeowners a blend of durability, speed, and eco-friendliness. Traditional wood-framed homes are prone to rot, pests, and fire, but steel frames resist these issues while lasting 30–50% longer. During fabrication, steel components are precision-cut and pre-drilled off-site, reducing on-site waste by up to 40%. For homeowners, this translates to shorter build times (4–8 weeks vs. 12+ weeks for wood) and lower long-term maintenance costs. Additionally, steel’s high recyclability (95% of scrap is reused) aligns with green building standards, making metal homes a sustainable choice for eco-conscious buyers.

In industrial and commercial projects, steel beam construction is the backbone of reliability. Pre engineered steel beams—whether I-beams, C-channels, or trusses—are engineered to handle extreme loads, from heavy machinery in factories to roof systems in large warehouses. Using finite element analysis (FEA), engineers optimize beam thickness and web design to minimize deflection under stress. For example, a 10m-span steel beam in a logistics hub can support 5-ton overhead cranes without sagging, ensuring safe and efficient operations. Unlike timber beams, steel resists warping, splitting, and moisture damage, making it ideal for harsh environments like coastal areas or chemical plants.

Pre engineered steel redefines what’s possible in metal structure construction by overcoming the limitations of conventional materials. While concrete structures require months of curing and are prone to cracking, steel structures go up in weeks, with bolted connections enabling quick adjustments. For large-scale projects like airports, stadiums, or multi-story parking garages, steel’s modular design allows components to be pre-assembled off-site, then lifted into place with cranes—an approach that reduces disruption to surrounding areas. Even in remote locations, steel structures thrive: lightweight yet strong, they minimize foundation requirements, cutting costs in challenging terrains.

The synergy between pre engineered steel and steel and construction drives innovation across industries. Architects appreciate steel’s design flexibility—they can create curved roofs, cantilevered extensions, and large glass façades that would be impossible with concrete. Contractors value its predictability: prefab steel components arrive on-site with pre-drilled holes and pre-welded connections, reducing errors and rework. For developers, steel’s speed-to-market is a game-changer: a 10,000ft² office building can be enclosed in just 6 weeks, allowing tenants to move in months earlier than with traditional methods. This partnership is not just about speed—it’s about building smarter, safer, and more sustainably.

For workshop steel applications, pre engineered steel is a cornerstone of productivity. Industrial workshops demand robust structures to support heavy equipment, high ceilings for overhead cranes, and durable finishes to withstand dust, chemicals, and temperature fluctuations. Steel frames, paired with corrugated metal cladding, provide airtight enclosures that protect machinery from the elements. Inside, steel mezzanines and elevated work platforms maximize vertical space, while pre-installed utility conduits (for electrical wiring, HVAC, and compressed air) streamline installation of production lines.

| Parameter | Detail | Benefit |

|---|---|---|

| Material Grade | ASTM A36/A992 (structural steel); G90 galvanized for corrosion resistance. | High strength-to-weight ratio; 50+ year lifespan. |

| Fabrication Tolerance | ±2mm for structural connections; ±1mm for cladding alignment. | Seamless on-site assembly; reduced rework. |

| Installation Speed | 50–70% faster than concrete; 1,000ft²/day for residential projects. | Faster ROI for developers; minimized disruption. |

| Sustainability | 95% recycled content; 30% lower carbon footprint vs. concrete. | Meets LEED/GRI certification; aligns with net-zero goals. |

*Required fields